Experienced Injection Mold Makers

Injection mold making is an essential part of the injection molding process, offering businesses and industries the chance to precisely create parts and components from a variety of materials. From plastic products to metal components, injection mold makers are experienced professionals who use complex processes to manufacture and develop a final product.

If you’re looking for an experienced and reliable injection mold making company, Coreprint Patterns is the team you can trust. We take a strategic approach to every order, ensuring that our customers receive the highest quality service and results in a timely and cost-effective manner. Our team is highly skilled and certified to both AS9100D and ISO 9001:2015 standards, offering you the assurance that each mold we produce meets or exceeds industry standards.

Furthermore, we are dedicated to the success of our customers – partnering with them throughout the entire process to ensure their goals are met with precision and accuracy. With Coreprint Patterns, you can rest assured knowing that you will get top-tier service combined with reliable results!

What is an Injection Mold?

An injection mold is a tool used in the process of injection molding to create custom parts and products with precise measurements, shapes, and sizes. Injection molds are frequently used to manufacture a wide variety of items including consumer products, medical devices, automotive parts and more.

Injection molds have many advantages over other manufacturing processes including low cost, superior quality control, increased production speed, reduced waste and improved safety during production due to its automated nature. With so many benefits associated with injection molding, it should come as no surprise that it has quickly become one of the most preferred methods for mass production today!

The Injection Molding Process

The injection molding process is a complex and precise manufacturing process that begins with the creation of plastic or metal injection molds. These molds are carefully crafted by our injection mold makers using high-precision tools and materials in order to meet exact specifications for each product. Once the mold is made, it is filled with molten plastic material or other specified material depending on the job requirements.

After being injected into the mold cavity, the material is allowed to cool, forming a precision shape and size. Finally, our expert team of mold makers perform detailed post-production processes to ensure your parts meet even the most demanding criteria of quality and accuracy. From concept to packaging, Coreprint Patterns provides excellent injection mold making services to help you get the perfect results you’re looking for.

What other types of molds can we create?

At Coreprint Patterns, we offer a variety of mold solutions to meet our customers’ diverse needs. Our aluminum molds are designed for low-volume production and can easily be modified, while metal molds provide a way to create high-quality, high-precision parts in large quantities. We also specialize in the creation of multi-cavity molds that use sophisticated molding machines to produce designs with intricate details. Whatever your requirements, we are able to deliver premier quality finished products every time!

Injection Molding Manufacturers

Mold manufacturers have been a critical part of the manufacturing industry for decades. As a leading injection mold manufacturer, Coreprint Patterns offers clients an array of injection molding services to meet their needs. Our experienced team offers tailored and innovative solutions that help produce high-quality results in a timely manner.

With our state-of-the-art facilities and professional staff, Coreprint Patterns stands above the competition for our commitment to quality and customer satisfaction.

Cost to Make an Injection Mold

The cost of making a mold depends on several factors, including the complexity of the final part design, size and type of material used, and production quantity. Generally, a plastic or metal injection molding part can range from a few hundred dollars for a simple design to tens of thousands of dollars for more complicated or larger molds.

For example, a single-cavity aluminum mold can cost around $1,500 while a multi-cavity steel tool with slider action can cost upwards of $25,000. The total cost also includes shipping and taxes.

How Long Does it Take to Make an Injection Mold?

The time it takes to make an Injection Mold typically ranges from a few weeks to several months, depending on the complexity of the design and production quantity. Simple molds can usually be completed in 1-2 weeks while more complex molds may take up to 10 weeks or more. Additionally, changes to the design may require additional time for redesign and testing. Furthermore, if the mold requires specialized cooling, water lines or other specialized services, this too can add additional lead time.

How are Molds Made?

Molds are made using a variety of materials such as metal, aluminum, certain plastics, rubber and more. The material used is typically dependent on the application and desired result.

The molds are created by either casting or injection molding methods. In the casting process, molten material is poured into a hollow chamber and allowed to cool and adopt its shape while in injection molding, molten material is forced into a pre-made cavity under pressure to create an exact replica of the desired product form. Additionally, post-molding processes are often used to refine the form and design of the injection molded product before it is complete.

Have Questions?

Plastic Injection Mold Making

Plastic mold manufacturing is a highly technical process that involves the machining of plastic injection molds from detailed designs. At Coreprint Patterns, we specialize in this process and understand the importance of precision and accuracy when it comes to creating quality products. Our expert plastic injection mold makers craft exact replicas of the desired product, ensuring that each part produced is identical to the next.

With our specialized services, companies seeking plastic injection molding can produce their parts quickly and cost-effectively as well as make efficient changes without having to remake entire molds. This allows for high-quality production with consistent results at a fraction of the cost compared to other methods – making it one of the most preferred choices for mass production today.

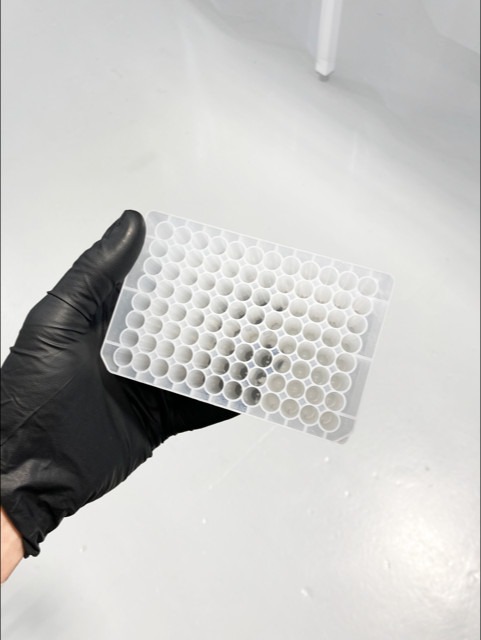

Watch the automated packaging of 96 deep well plates in our clean room. Visit our YouTube channel for more videos.

Your Go-To Plastic Prototype Manufacturer

Coreprint Patterns is your go-to company for plastic prototype manufacturing. We utilize state-of-the-art injection molding processes to create high-quality prototypes, short run production and custom molds. We offer fast turnaround times, quick responses, cost effective solutions and complete satisfaction for all their customers.

With an experienced team of engineers and machinists, our company can develop any plastic prototype from concept to reality with the highest level of quality control and attention to detail. Additionally, our services include 3D printing, CNC machining capabilities, hot runner systems and post-molding processes. Overall, we offer a wide range of services for all types of prototyping requirements.

Injection Mold Design

Coreprint Patterns specializes in tailored injection mold design and engineering. Our experienced engineers create plastic injection molded products using 3D CAD/CAM software to ensure the highest accuracy and quality. We focus on providing cost-effective solutions that guarantee complete customer satisfaction.

In addition to standard injection mold design, we can also provide designing services for multi cavity and steel molds, multifamily molds, hot runner molds, die casting, prototype and production runs as well as other custom requirements. From concept to completion, Coreprint Patterns provides superior quality plastic parts for any plastic injection molding or design project.

Aerospace Parts Manufacturing

Injection mold making is a critical step in the manufacturing of aerospace parts. Injection molds are used to create complex and intricate shapes that can withstand high temperatures, pressures and other extreme conditions. By using injection molds for aerospace parts manufacturing, companies can ensure that their products are durable, reliable and have a consistently high quality level of accuracy.

By leveraging the expertise of our team of skilled plastic mold makers at Coreprint Patterns, aerospace manufacturers can rely on us to produce top-of-the-line plastic injection molds that meet their exact specifications.

Medical Mould

Manufacturing

Injection mold making is an incredibly useful tool for the medical industry. Medical mould manufacturers use injection molds to create high-precision products that are crucial for medical equipment. These products must be designed and manufactured with precise accuracy in order to meet the industry’s exacting standards, and injection moulds can be used to achieve this.

At Coreprint Patterns, medical device manufacturers can trust our team of experienced injection mold part makers to ensure their products comply with all rules and standards of quality. When you choose us, your medical devices will perform as expected every time.

Automotive Parts Manufacturing

Injection mold making is a key part of the automotive industry, as it is used to create complex parts and automotive components that are necessary for a vehicle’s performance and safety. By utilizing injection molds, automotive manufacturers can ensure that their products meet the highest standards for accuracy and quality.

At Coreprint Patterns, our talented team of plastic mold makers can help you get the right plastic injection molds made that meet your exact specifications, allowing you to produce reliable components quickly while maintaining a consistently high level of quality. With our expertise, your next project is sure to be a success.

Custom Molded Products

Custom molded products are a great way to make unique and personalized items for any purpose or occasion. Mold Making is an essential part of the process, as it helps create the precise shapes and sizes needed to produce consistent results. At Coreprint Patterns, we are experts in creating custom molds designed around your exact specifications, ensuring that no detail is overlooked when it comes to achieving the desired outcome.

Our experienced team of plastic mold makers will work closely with you every step of the way providing engineering support and to ensure that your product is exactly what you envisioned. With cutting-edge technology, premium materials, and our commitment to excellence, you can trust that when you choose Coreprint Patterns for your custom injection molded product needs, the results will be flawless.

We Are Your Molding Supplier

Coreprint Patterns is the perfect choice when it comes to choosing a manufacturing partner. We consistently strive to exceed customer expectations with our quality products, reliable delivery, and competitive prices. What sets us apart from the rest is that we are an AS9100D and ISO 9001:2015 certified company, which guarantees the highest level of quality assurance.

In addition, we take pride in being a ‘strategic partner’ for our customers, providing added value through personalized consultation services and detailed production follow up. With us as your molding supplier, you can rest assured knowing that your project will be managed with dedication and commitment.